Search This Supplers Products:Injection Mold Designplastic injection moldMolding ServiceCustom Moldcase molddie casting mold

- Home

- About us

- Products

- 3D printing & Prototype

- Home Appliances Plastic Mould/Molding

- Overmolding Mould/Molding

- Electronic Plastic Mould/Molding

- Medical Plastic Mould/Molding

- Industrial Plastic Mould/Molding

- Commodity Plastic Mould/Molding

- Auto plastic mould/molding

- Packaging Plastic Mould/Molding

- Stamping Mould & Die Casting

- Silicone Mould/Molding

- Blowing Mould/Molding

- Faqs

- Factory

- Mold tooling

- Mould steel

- Good Factory

- Plastic Material

- surface treatment

- Delivery time

- Payment terms

- Yunpeng advantage

- Yunpeng mould advantage 2

- 3D Drawing Format

- Yunpeng Certificate

- Service

- Manufacture plastic parts

- 3 D Printing

- Delivery Terms

- Die casting

- Quality

- Mold Wiki

- Mold Layout/Design

- Mold Layout Design

- do you know about" Injection molding"

- Mold Structure

- Mold problems

- Hot Runner

- Two shot plastic injection molding

- Cavity

- Parting Line

- How to Determine Parting Line of mold products?

- News

- YP mould

- Update news about our YP plastic injection mould

- How to get the injection products of the best prec

- Mold knowledge

- Customers visit our factory

- How to make injection mold with high qulaity?

- two shot plastic injection molding and it's functi

- Two shot plastic injection molding and it's functi

- What is a hot runner mold

- Certificate

- Contact us

How to control Insert Mold with wall Temperature

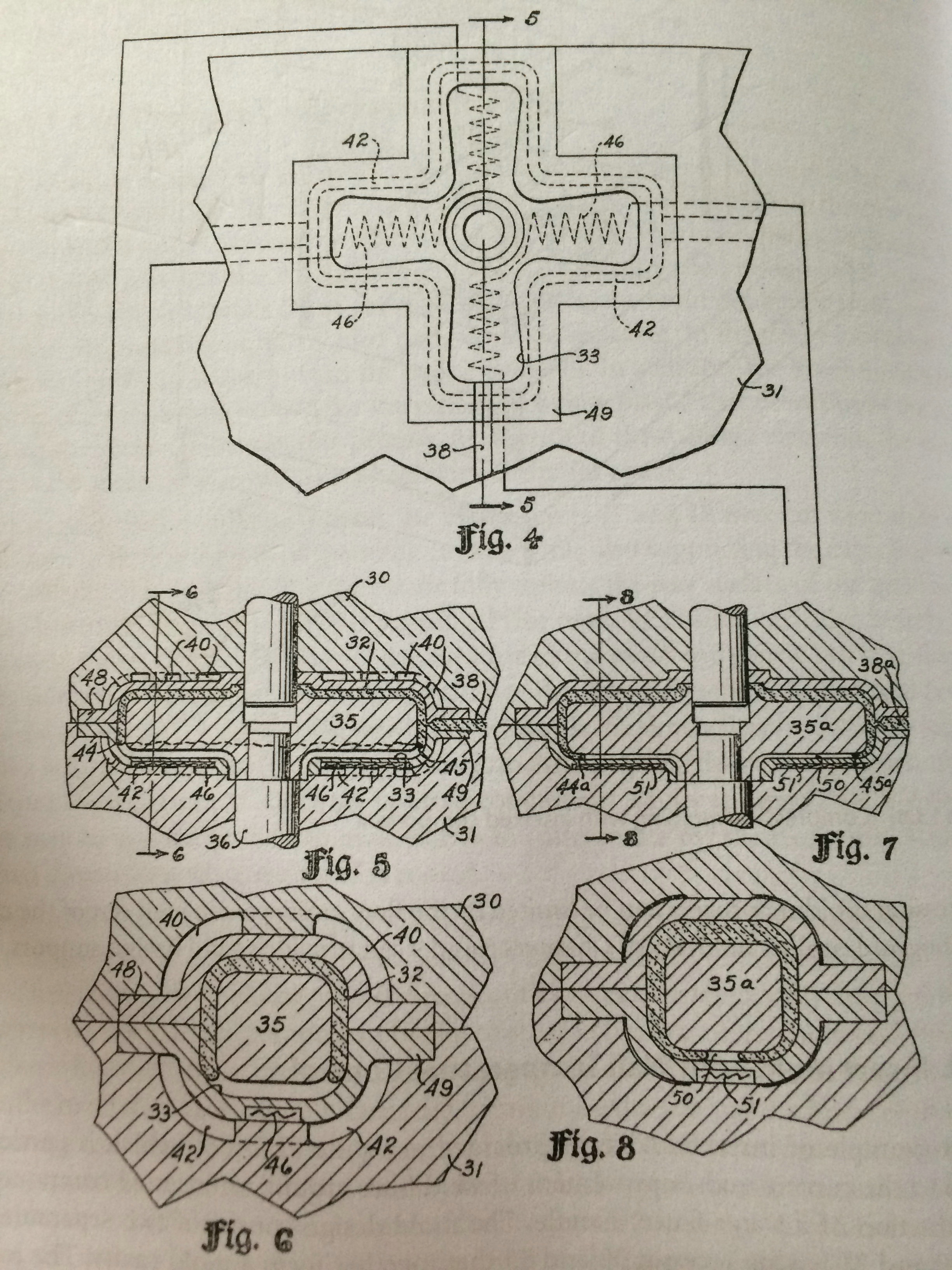

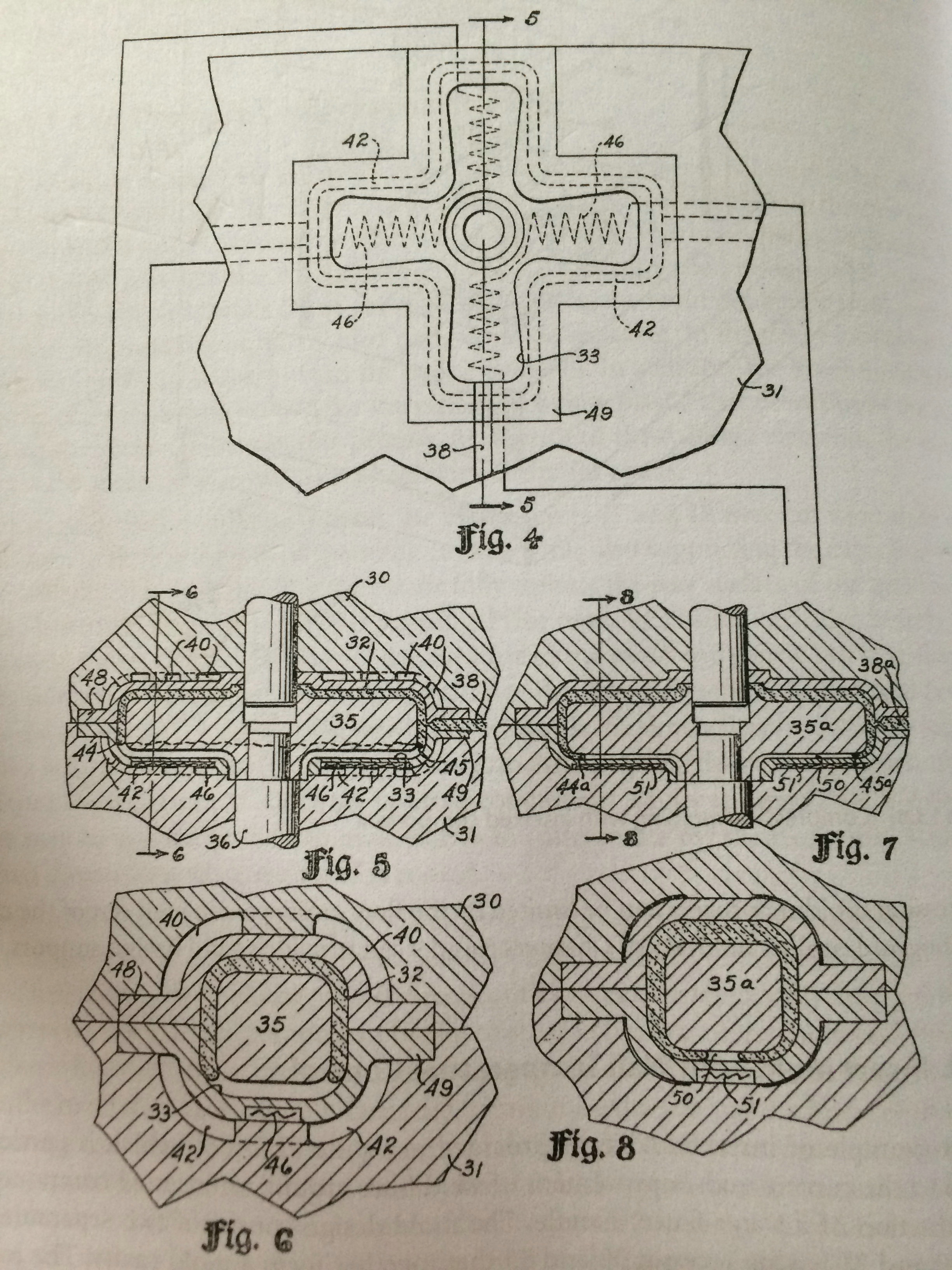

Another example of insert molding is provided in Figure 13.7[53],which is particularly directed to the control and improvement of weld lines around an inserted component for the production of a water faucet handle.The mold design consist of two separable mold halves 30and 31 having recesses 32and 33 that together form a mold cavity. The inserted component 35 is held in position by two opposing pins 36. After mold closure and prior to mold filling, asubstabtially uniform cavity thickness exists between the inserted component 35 and the mold halves 30and 31.In this mold design, the mold wall temperture of the mold is locally controlled by the flow of a controlled fluid through channels 40 and 42.Different fluids such as water,oil,or steam can be provided to different portions of the mold at different temperatures.