Search This Supplers Products:Injection Mold Designplastic injection moldMolding ServiceCustom Moldcase molddie casting mold

- Home

- About us

- Products

- 3D printing & Prototype

- Home Appliances Plastic Mould/Molding

- Overmolding Mould/Molding

- Electronic Plastic Mould/Molding

- Medical Plastic Mould/Molding

- Industrial Plastic Mould/Molding

- Commodity Plastic Mould/Molding

- Auto plastic mould/molding

- Packaging Plastic Mould/Molding

- Stamping Mould & Die Casting

- Silicone Mould/Molding

- Blowing Mould/Molding

- Faqs

- Factory

- Mold tooling

- Mould steel

- Good Factory

- Plastic Material

- surface treatment

- Delivery time

- Payment terms

- Yunpeng advantage

- Yunpeng mould advantage 2

- 3D Drawing Format

- Yunpeng Certificate

- Service

- Manufacture plastic parts

- 3 D Printing

- Delivery Terms

- Die casting

- Quality

- Mold Wiki

- Mold Layout/Design

- Mold Layout Design

- do you know about" Injection molding"

- Mold Structure

- Mold problems

- Hot Runner

- Two shot plastic injection molding

- Cavity

- Parting Line

- How to Determine Parting Line of mold products?

- News

- YP mould

- Update news about our YP plastic injection mould

- How to get the injection products of the best prec

- Mold knowledge

- Customers visit our factory

- How to make injection mold with high qulaity?

- two shot plastic injection molding and it's functi

- Two shot plastic injection molding and it's functi

- What is a hot runner mold

- Certificate

- Contact us

Buying Tips in China

time2017/09/15

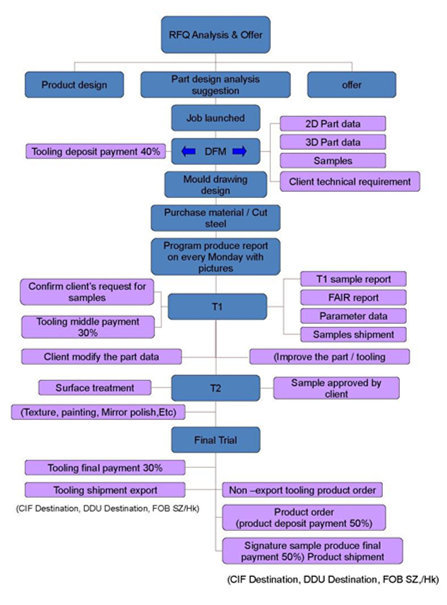

From inquiry to Po closed, we have a standard procedure to follow, it helps both internal and customers always clear where we are. The transition of each step would be easier and smoother as well.

Order process of export injection plastic mold:

Order process of export injection plastic mold:

- Received 2D/3D part drawing from customer, project manager hold kick-out meeting to review data from customer with mold designers, mold makers, QA manager, PMC. Collect all the information have been discussed, send DFM report to customer for confirmation.

- DFM report contains all the necessary information before design and manufacture. Mold gating way, ejection way, layout of injection pins, layout of parts, mold parting line, cooling line. Special structure feature like sliders, angle lifters, finish of mold core and cavity, engraving etc.

- After all details have been discussed through, mold design start and 2d layout of mold design would be provided to customer within 1-3 days ,mold design in 3D takes 3-7 days depends on the complexity of the mold.

- Send mold design to customer for approval, start to order mold steel, mold base, accessories after deposit. A process report would be submitted and show all the process planned. Weekly report would be follow as the mold manufacturing process move forwarder until it’s finished.

- The first time’s mold trial tell if all the mechanism of mold work properly, geometry of part is correct, we check mold cooling system, mold injection system, mold ejection system etc. after proper modification, T1 molded plastic samples would be submitted to customer together with dimension report, injection molding parameter. normally it’s 90% of perfection.

- Get comments for sample improvement, functionality, appearance, dimensionally .after corrections, finish the texture/polishing, engraving etc, send the samples for final approval.

- Do a small automatically run and CPK report study to make sure tooling stability.

- Packing the mold with wooden box, if the mold shipped by sea, we pay specially attention to the vacuum packing to prevent from rusty. Packages include all 2d/3d mold design drawing, NC programming data, copper, spare parts, interchangeable inserts, etc.

- Follow up the work performance of the mold in customers' plant and provide necessary services.