Search This Supplers Products:Injection Mold Designplastic injection moldMolding ServiceCustom Moldcase molddie casting mold

- Home

- About us

- Products

- 3D printing & Prototype

- Home Appliances Plastic Mould/Molding

- Overmolding Mould/Molding

- Electronic Plastic Mould/Molding

- Medical Plastic Mould/Molding

- Industrial Plastic Mould/Molding

- Commodity Plastic Mould/Molding

- Auto plastic mould/molding

- Packaging Plastic Mould/Molding

- Stamping Mould & Die Casting

- Silicone Mould/Molding

- Blowing Mould/Molding

- Faqs

- Factory

- Mold tooling

- Mould steel

- Good Factory

- Plastic Material

- surface treatment

- Delivery time

- Payment terms

- Yunpeng advantage

- Yunpeng mould advantage 2

- 3D Drawing Format

- Yunpeng Certificate

- Service

- Manufacture plastic parts

- 3 D Printing

- Delivery Terms

- Die casting

- Quality

- Mold Wiki

- Mold Layout/Design

- Mold Layout Design

- do you know about" Injection molding"

- Mold Structure

- Mold problems

- Hot Runner

- Two shot plastic injection molding

- Cavity

- Parting Line

- How to Determine Parting Line of mold products?

- News

- YP mould

- Update news about our YP plastic injection mould

- How to get the injection products of the best prec

- Mold knowledge

- Customers visit our factory

- How to make injection mold with high qulaity?

- two shot plastic injection molding and it's functi

- Two shot plastic injection molding and it's functi

- What is a hot runner mold

- Certificate

- Contact us

Understanding the Basics of Plastic Injection Molding Process

publisherTea

time2017/10/23

Understanding the Basics of Plastic Injection Molding Process

Plastic injection molding process begins with the gravity feeding of polyolefin pellets from a hopper into the plasticating /injection unit of the molding machine. Heat and pressure are applied to the polyolefin resin, causing it to melt and flow. The melt is injected under high pressure into the injection mold. Pressure is maintained on the material in the cavity until it cools and solidifies. When the plastic part temperature lower than the material's distortion temperature, the mold opens and the plastic part is ejected.

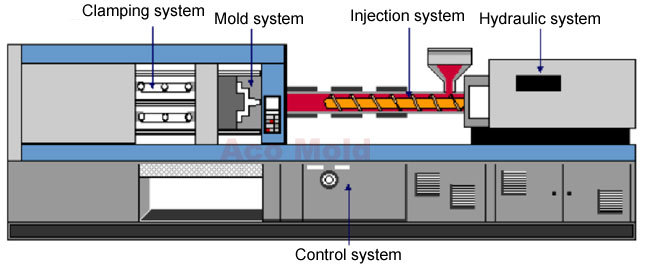

The complete injection process is called a molding cycle. The period between the start of the injection of the melt into the mold cavity and the opening of the mold is called the clamp close time. The total injection cycle time consists of the clamp close time plus the time required to open the mold, eject the plastic part, and close the mold again, the injection molding machine transfer the resin into molded parts through a melt down, injection, pack, and cool down cycle. A plastic injection molding machine includes the following major components as below.

Injection system: feed the raw materials into cylinder, heat up and melt it down, push the melted materials into the cavity through the spure.

Hydraulic system: to provide the force of injection.

Mold system: to load and assemble the mold.

Clamping system: to provide packing force.Control system: to control action, cooling system.

- if you need help, pls contact me, I am Tea, my email is injectionmold2006..........com

- whatsapp+8615958816137 skype:injectionmold2006..........com