Search This Supplers Products:Injection Mold Designplastic injection moldMolding ServiceCustom Moldcase molddie casting mold

- Home

- About us

- Products

- 3D printing & Prototype

- Home Appliances Plastic Mould/Molding

- Overmolding Mould/Molding

- Electronic Plastic Mould/Molding

- Medical Plastic Mould/Molding

- Industrial Plastic Mould/Molding

- Commodity Plastic Mould/Molding

- Auto plastic mould/molding

- Packaging Plastic Mould/Molding

- Stamping Mould & Die Casting

- Silicone Mould/Molding

- Blowing Mould/Molding

- Faqs

- Factory

- Mold tooling

- Mould steel

- Good Factory

- Plastic Material

- surface treatment

- Delivery time

- Payment terms

- Yunpeng advantage

- Yunpeng mould advantage 2

- 3D Drawing Format

- Yunpeng Certificate

- Service

- Manufacture plastic parts

- 3 D Printing

- Delivery Terms

- Die casting

- Quality

- Mold Wiki

- Mold Layout/Design

- Mold Layout Design

- do you know about" Injection molding"

- Mold Structure

- Mold problems

- Hot Runner

- Two shot plastic injection molding

- Cavity

- Parting Line

- How to Determine Parting Line of mold products?

- News

- YP mould

- Update news about our YP plastic injection mould

- How to get the injection products of the best prec

- Mold knowledge

- Customers visit our factory

- How to make injection mold with high qulaity?

- two shot plastic injection molding and it's functi

- Two shot plastic injection molding and it's functi

- What is a hot runner mold

- Certificate

- Contact us

Foundry Price 2017 Hottest Toy Metal Fidget Spinner Finger Spinner Toy

- FOB Price

US $2000.001 - 2 piece

- group name

- Plastic Baby Use&Toy Mold

- Min Order

- 1 piece

- brand name

- YP Plastic Injection Molding

- model

- YP-1

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union, Cash

- update time

- Wed, 17 Oct 2018 17:30:11 GMT

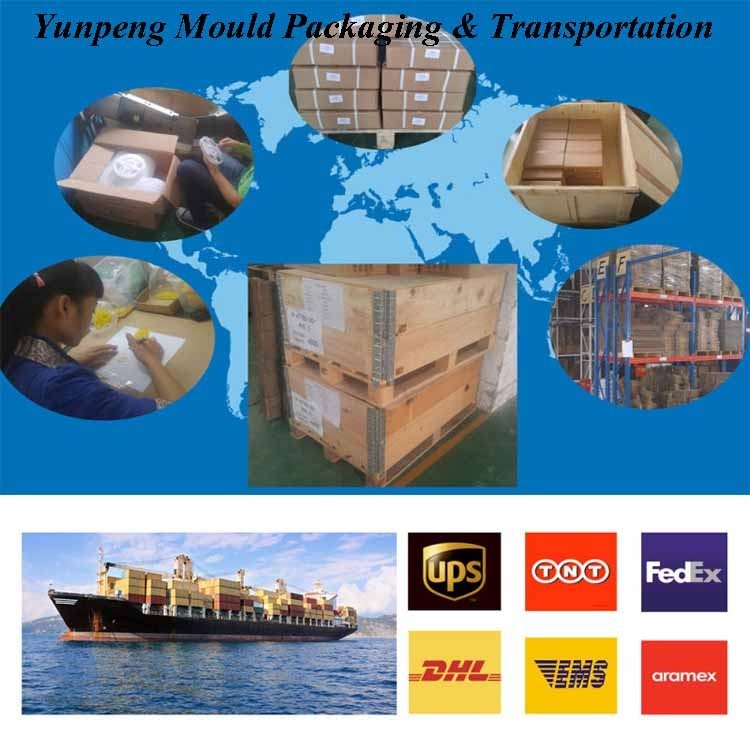

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Foundry Price 2017 Hottest Toy Metal Fidget Spinner FingerSpinner Toy

A fun and easy way to increase focus and concentration while decreasing stress.To design and create a high performance, multifunctional, customizable, and affordable fidget toy. lt is the unique fidget solution for all ages and fidgeting needs.Great For Fidgety Hands, ADD & ADHD Sufferers Helps Relieve Stress Perfect size suitable for Adults and kids Easy To Carry,Small,Simple,Discrete and Fun,also effective for Focus and Deep Thought SLA technology.

We can not only provide products for you,but also provide mold making with good quality!!welcome to email to me ,this is cherry,i am here to serve you ! ! !

Product Introduce

product name: Fidget toy hand spinner

Material: ABS Plastic + Bearing (steel )

size :8*22*7mm

Color: Black,White,Red,Blue,Yellow,Green (IF you need another colors ,we can customized for you )

Packing: paper box--carton--pallet or as customer's request

Bearing:608-2rs, steel bearingBrand we can produce your own brand, OEM is highly supported

Weight: 60g/pc

More Specifications

1.Bore Size :(d) 8mm

2.Outer Size: (D) 22mm

3.Brand Name: OEM

4.Our Bearing Features: High precision,long life, low noise, advanced technology, low vibration

5.Main Market: US,UK,Mexico,Colombia,East Asia,South Africa,Austrilia

Mould & Products Show

Related products to show

Glance of workshop

Packaging & Shipping

- Packing With Wood Box for Transportation or as request.

- Shipping around 30 days.

Payment

Paypal , T/T , L/C , D/A , D/P , Western Union , MoneyGram , Others.

Company Information:

- Our factory integrates mold design, manufacturing, and injection molding. It is a Director Unit of YuyaoMold Industry Association, and a key backbone enterprise in Yuyao’s plastic mold industry.

- We are specialized in designing & manufacturing plastic mold & plastic products, concerning home daily, auto part, household appliances, medical beauty equipment, transport facilities and many different kinds of toy for many countries. We have abundant experience for performance of different kinds of plastic and can offer perfect OEM & ODM service for plastic mold and plastic products.

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make stamping molds according to our customer’s requirements.

A2: With our CAD systems we can accept following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

A3: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

A4: Yes, We can provide steel certificate or hardness certificate to prove.

A5: Yes, As plastic mold fatory, we have long_term cooperated subsidiary factories that do those processes.They are professional and well reputed in our local market.

A6: It all depends on the mold’s size and complexity.Normally, the lead time is 25_45 days.If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

A7: Yes, we will provide spare parts for the mold if needed or required by client.

A8: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any

FAQ About Molded Products

Q9: How many injection plastic mouldings machines do you have?

A9: We have 40 sets of ?plastic Injection Mouldings machines.

A10: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

A11: We are specialized in producing plastic products with the following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q12: Can you deliver the plastic moulds or plastic products to our factory?

A12: Yes, We have cooperated with many international logistics companies for years.

And we have full experience to manage the delivery directly to the client's factory or

Contact Us

Thanks for visiting!

Warmly welcome to e-mail to me or chat with on line.