Search This Supplers Products:Injection Mold Designplastic injection moldMolding ServiceCustom Moldcase molddie casting mold

- Home

- About us

- Products

- 3D printing & Prototype

- Home Appliances Plastic Mould/Molding

- Overmolding Mould/Molding

- Electronic Plastic Mould/Molding

- Medical Plastic Mould/Molding

- Industrial Plastic Mould/Molding

- Commodity Plastic Mould/Molding

- Auto plastic mould/molding

- Packaging Plastic Mould/Molding

- Stamping Mould & Die Casting

- Silicone Mould/Molding

- Blowing Mould/Molding

- Faqs

- Factory

- Mold tooling

- Mould steel

- Good Factory

- Plastic Material

- surface treatment

- Delivery time

- Payment terms

- Yunpeng advantage

- Yunpeng mould advantage 2

- 3D Drawing Format

- Yunpeng Certificate

- Service

- Manufacture plastic parts

- 3 D Printing

- Delivery Terms

- Die casting

- Quality

- Mold Wiki

- Mold Layout/Design

- Mold Layout Design

- do you know about" Injection molding"

- Mold Structure

- Mold problems

- Hot Runner

- Two shot plastic injection molding

- Cavity

- Parting Line

- How to Determine Parting Line of mold products?

- News

- YP mould

- Update news about our YP plastic injection mould

- How to get the injection products of the best prec

- Mold knowledge

- Customers visit our factory

- How to make injection mold with high qulaity?

- two shot plastic injection molding and it's functi

- Two shot plastic injection molding and it's functi

- What is a hot runner mold

- Certificate

- Contact us

Low price Rapid silicone 3D printing model and CNC quick prototype for Aluminum parts machining

- FOB Price

US $2000.001 - 2 piece

- group name

- 3D printing & Prototype

- Min Order

- 1 piece

- brand name

- YP Plastic Injection Molding

- model

- YP-Mould

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union, Cash

- update time

- Tue, 16 Jan 2018 11:33:11 GMT

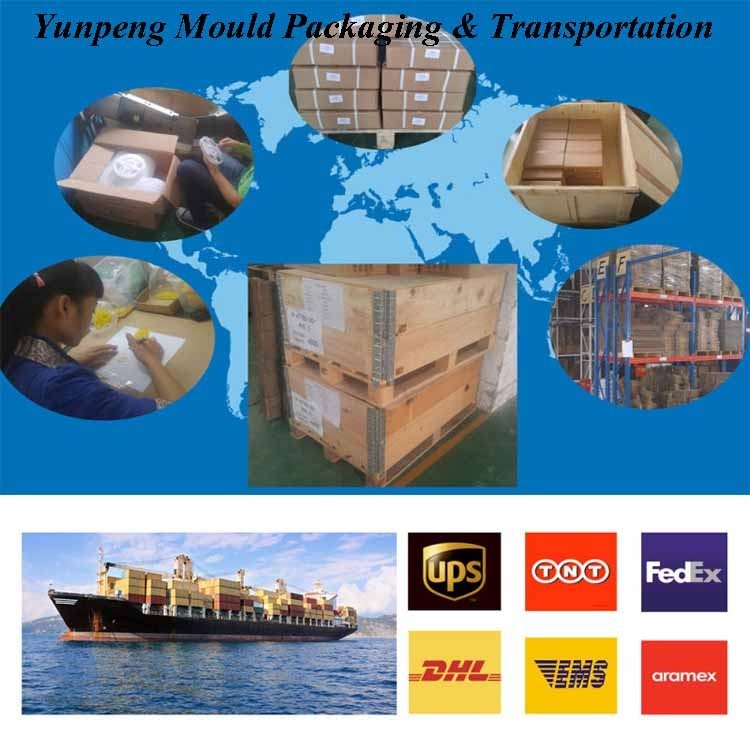

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Low price Rapid silicone 3D printing model and CNC quickprototype for Aluminum parts machining

Introduction

Plastic Prototypes & 3D Prototyping

Building die cast or investment cast shapes from metal normally takes weeks of production. However, modern metal prototyping technology offers a much faster and more cost-effective solution in the form of rapid prototypes. Indeed, a rapid prototyping machine can produce even the most complex metal shapes in as short a period as a single afternoon.

We can not only provide 3d printing parts for you,but also provide mold making with good quality! welcome to email to me ,this is cherry,i am here to serve you ! ! !

Mould & Products Show

Related products to show

Glance of workshop

Packaging & Shipping

- Packing With Wood Box for Transportation or as request.

- Shipping around 30 days.

Payment

Paypal , T/T , L/C , D/A , D/P , Western Union , MoneyGram , Others.

Company Information:

- Our factory integrates mold design,manufacturing,and Injection molding.It is a Director Unit of YuyaoMold Industry Association, and a key backbone enterprise in Yuyao’s plastic mold industry.

- We are specialized in designing & manufacturing plastic mold & plastic products, concerning home daily, auto part, household appliances, medical beauty equipment, transport facilities and many different kinds of toy for many countries. We have abundant experience for performance of different kinds of plastic and can offer perfect OEM & ODM service for plastic mold and plastic products.\

Contact Us