Search This Supplers Products:Injection Mold Designplastic injection moldMolding ServiceCustom Moldcase molddie casting mold

- Home

- About us

- Products

- 3D printing & Prototype

- Home Appliances Plastic Mould/Molding

- Overmolding Mould/Molding

- Electronic Plastic Mould/Molding

- Medical Plastic Mould/Molding

- Industrial Plastic Mould/Molding

- Commodity Plastic Mould/Molding

- Auto plastic mould/molding

- Packaging Plastic Mould/Molding

- Stamping Mould & Die Casting

- Silicone Mould/Molding

- Blowing Mould/Molding

- Faqs

- Factory

- Mold tooling

- Mould steel

- Good Factory

- Plastic Material

- surface treatment

- Delivery time

- Payment terms

- Yunpeng advantage

- Yunpeng mould advantage 2

- 3D Drawing Format

- Yunpeng Certificate

- Service

- Manufacture plastic parts

- 3 D Printing

- Delivery Terms

- Die casting

- Quality

- Mold Wiki

- Mold Layout/Design

- Mold Layout Design

- do you know about" Injection molding"

- Mold Structure

- Mold problems

- Hot Runner

- Two shot plastic injection molding

- Cavity

- Parting Line

- How to Determine Parting Line of mold products?

- News

- YP mould

- Update news about our YP plastic injection mould

- How to get the injection products of the best prec

- Mold knowledge

- Customers visit our factory

- How to make injection mold with high qulaity?

- two shot plastic injection molding and it's functi

- Two shot plastic injection molding and it's functi

- What is a hot runner mold

- Certificate

- Contact us

OEM plastic shell injection moulding for industrial equipment

- group name

- Industrial Plastic Mould/Molding

- Min Order

- 1 piece

- brand name

- YP Plastic Injection Molding

- model

- OEM plastic shell injection moulding for industria

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union, Cash

- update time

- Fri, 22 Dec 2017 11:08:03 GMT

Paramtents

Product injection mold tooling factory for Cooler Fan cove

Shaping Mode Plastic Injection Mould

Runner hot runner or cold runner plastic injection mold tooling

Parts Material ABS, PS, PP, PMMA, PC, PA66, PC+abs and so on

Prouducts Material Steel Metal

Cavity single or multi cavity Plastic Injection molding parts

Mold life shots 300,000 to 1,000,000 shots

Mold base LKM, DME, HASCO, FUTABA

Mold Finish Engrave, Texture, Harden, etc.

Steel material NAK80, 718H, P20, 2738

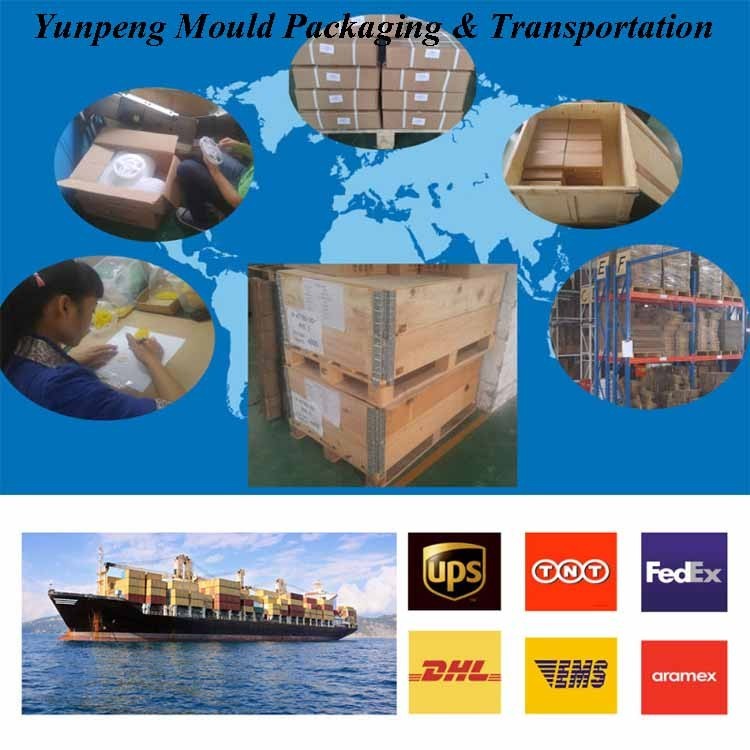

Packging & Delivery

-

Min Order1 piece

Briefing

1. Free 3 d Drawing service. 2. 2 after sales team. 3. On time delivery

Detailed

OEM plastic shell injection moulding for industrial equipment

Why choose us?

Yunpeng Mold Factory focus on injection mold more than 15 years.(Click link to see us on youtube)

1. Quality is our soul!

2. Free 3 d Drawing service

3. 2 special after sales team to help you solve any problem.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date.

5. Time is gold for you and for us, so we have professional team work and production line.

6. Plastic Injection Mould OEM & ODM Services

7. ISO 9001, ISO 14001 Certified Factory

8. Attachment is our latest finished moulds.

| Name | Description | |

| Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) | |

| Mould base | Standard mould base, LKM, HASCO etc. | |

| Cavity | Single/multi | |

| Runner | Hot/cold | |

| Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc | |

| Cooling system |

| |

| Design software | UG, PROE, CAD, CAXA etc. | |

| Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. | |

| Surface treatment | Polish, texture, sand blasting, chrome plating | |

| Mould life | 300,000-1,000,000 shots | |

| Delivery time | 15-45days | |

| Pacakge |

| |

| Specification | As per customer's requirements |